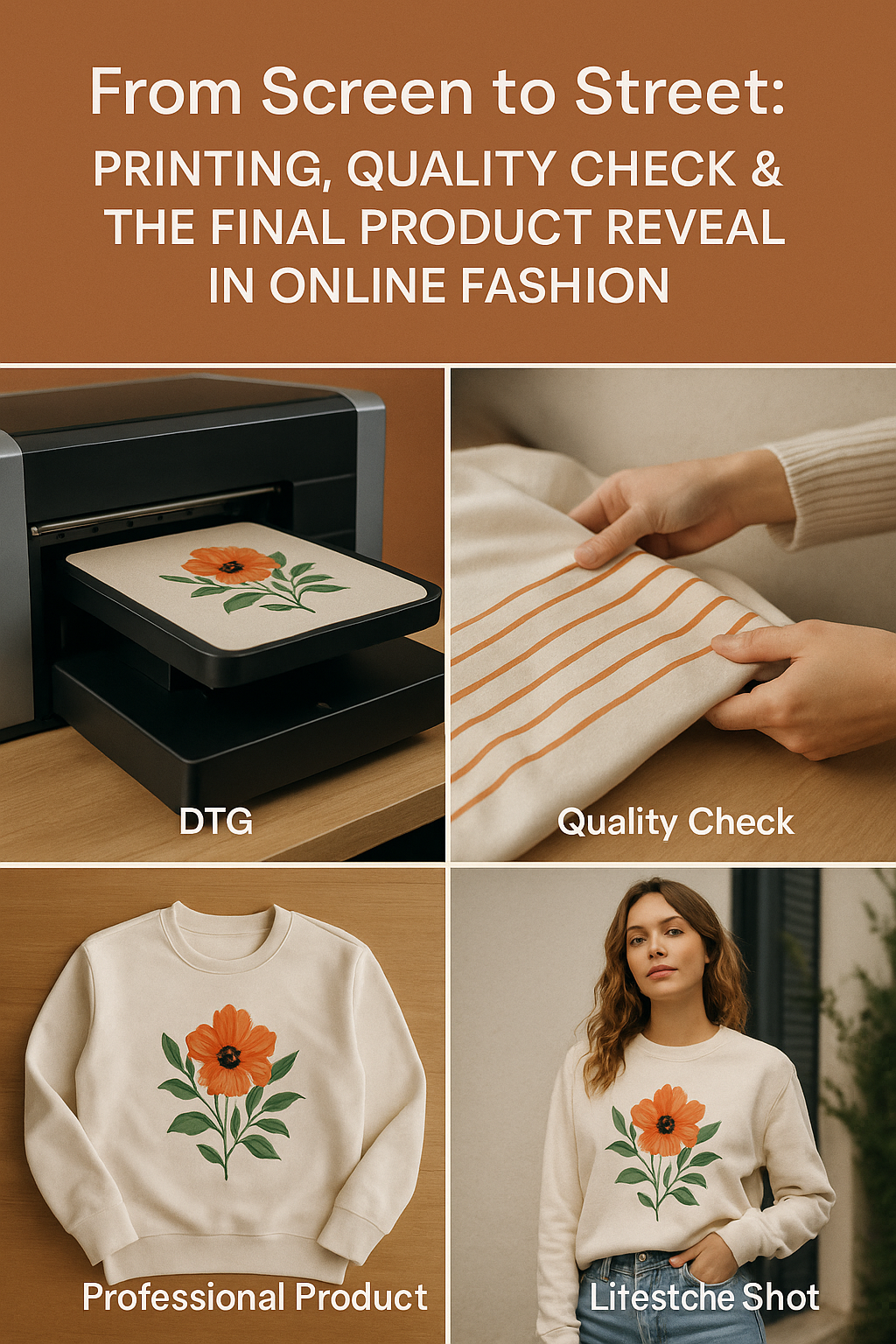

From Screen to Street: Printing, Quality Check & The Final Product Reveal in Online Fashion

Share

When it comes to online fashion retail, the magic doesn’t stop at designing — it’s the production stage that transforms a concept into something your customers can actually wear, flaunt, and fall in love with. Whether you’re running a print-on-demand store or a full-fledged apparel brand, mastering the printing, quality control, and final presentation stages is critical for success.

Industry Context & Market Trends

In 2025, consumers are demanding premium quality, fast fulfillment, and visually stunning products more than ever. According to a Statista survey, over 60% of online fashion shoppers say product quality directly impacts brand loyalty, and unboxing experience plays a huge role in repeat purchases.

With the rise of DTG (Direct-to-Garment), sublimation, and embroidery printing, small and mid-sized brands can now compete with major labels by offering custom designs without the massive upfront costs of bulk manufacturing. Platforms like Printful, Qikink, and Gelato have set new standards — eco-friendly inks, high-definition prints, and fabric-specific printing methods are now expected, not optional.

Challenges & Opportunities

Challenges:

-

Maintaining color accuracy across different fabric types.

-

Preventing print cracking or fading after multiple washes.

-

Balancing cost vs. premium finishes (embroidery vs. DTG).

-

Creating consistency in mass personalization orders.

Opportunities:

-

Offering limited-edition prints to drive urgency.

-

Leveraging eco-friendly printing as a brand USP.

-

Using AI-generated mockups and AR previews to boost pre-sales.

-

Incorporating sustainable fabrics for both style and ethics.

Actionable Strategies for Success

1️⃣ Choose the Right Printing Method

-

DTG Printing – Best for full-color, detailed designs on cotton blends. Works well for short runs and trending designs.

-

Sublimation – Perfect for polyester and all-over prints (AOP tote bags, sportswear).

-

Embroidery – Ideal for premium branding on caps, hoodies, and polos. Adds a tactile, luxury feel.

💡 Tip: Match your printing method to the product’s use case. For example, sublimation for activewear, embroidery for caps, DTG for fashion tees.

2️⃣ Implement Rigorous Quality Checks

-

Color Accuracy: Compare printed output against Pantone color charts.

-

Fabric Feel: Ensure the print doesn’t make the garment stiff or uncomfortable.

-

Wash Test: Check durability after at least 3–5 washes.

-

Thread & Stitching: For embroidery, inspect thread tension and edge finishing.

3️⃣ Professional Product Photography

Your product photos are your digital handshake. Poor images can kill a great product.

-

Flat Lay Shots: Highlight design clarity.

-

Close-ups: Show print texture and stitching quality.

-

Lifestyle Shots: Use models or real customers to show fit and feel — especially important for Instagram & Pinterest audiences.

-

Video Clips: Short reels showing fabric movement and unboxing boost engagement.

Future Outlook & Predictions

The next few years will see:

-

Hybrid printing methods combining DTG + embroidery for unique textures.

-

On-demand manufacturing in micro-warehouses to speed up delivery.

-

AI-powered print preview tools that let customers see how designs will age over time.

-

Sustainability-first branding, where eco-friendly inks and recycled fabrics aren’t just marketing — they’re the norm.

Brands that embrace high-quality production + aesthetic marketing will dominate, while those cutting corners will struggle to retain customers.

Final Call-to-Action

Ready to take your designs from concept to customer-ready perfection? At eHypermart.in, we combine the latest printing tech, meticulous quality checks, and professional visuals to deliver fashion that feels as good as it looks.